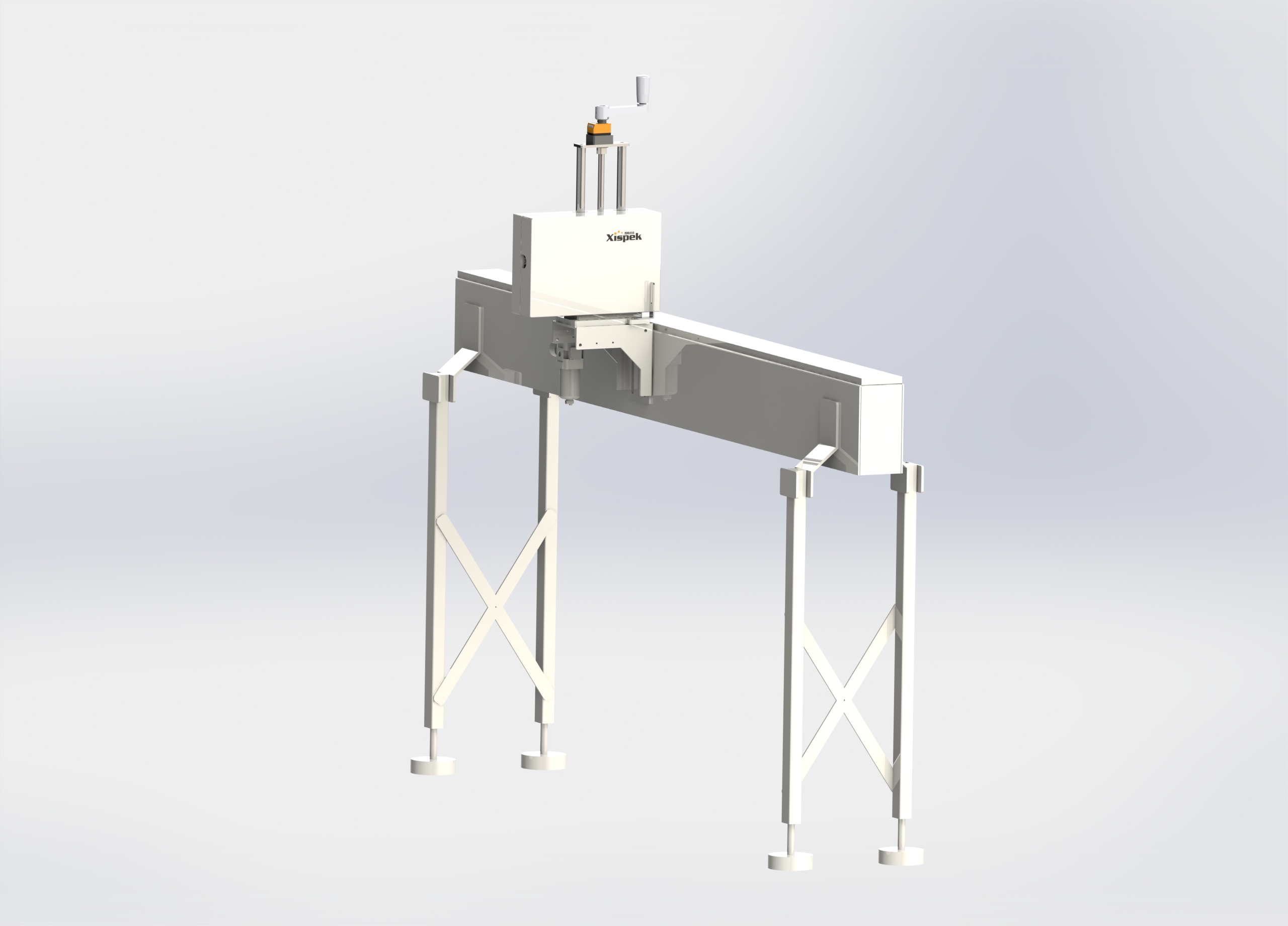

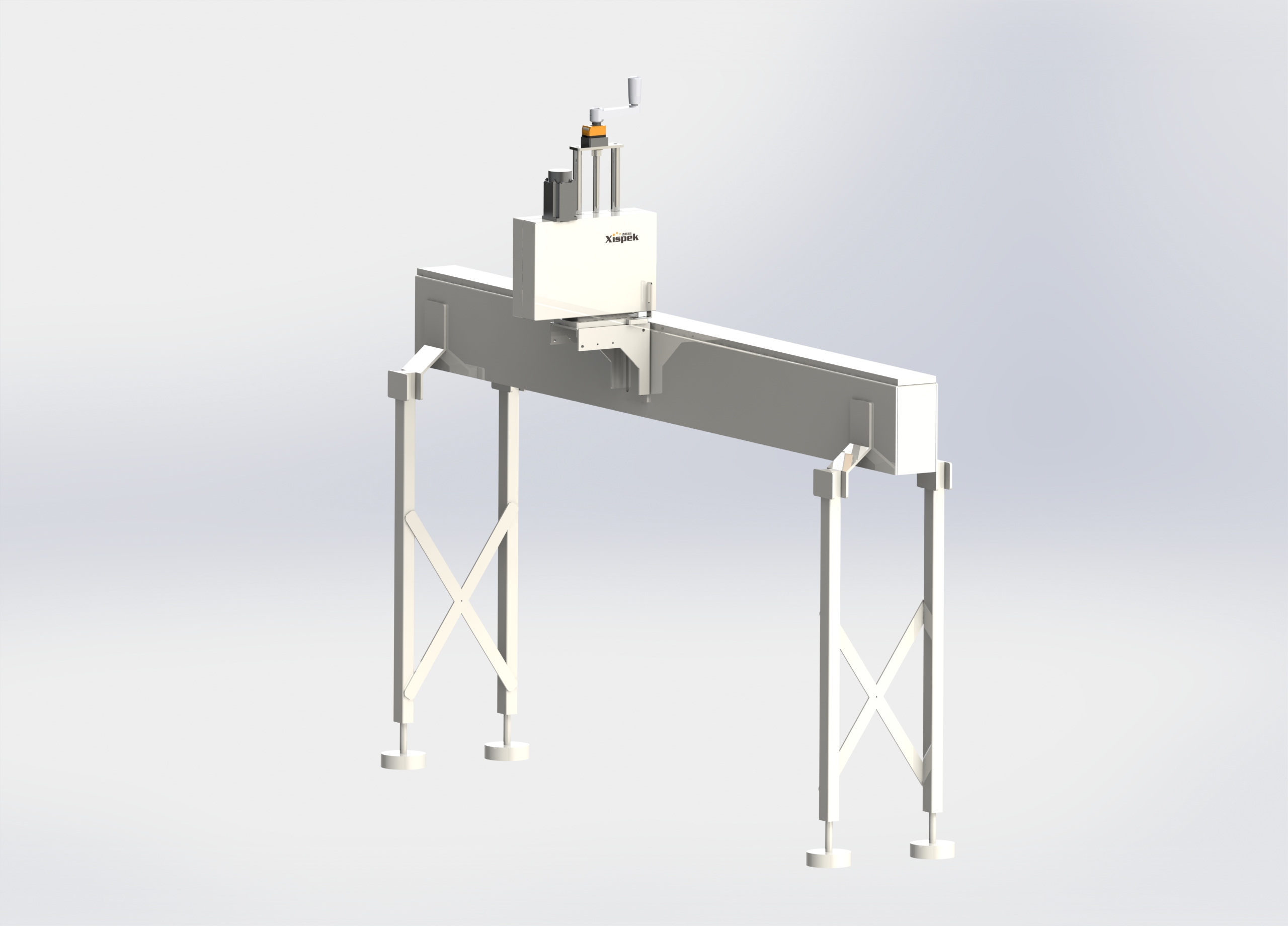

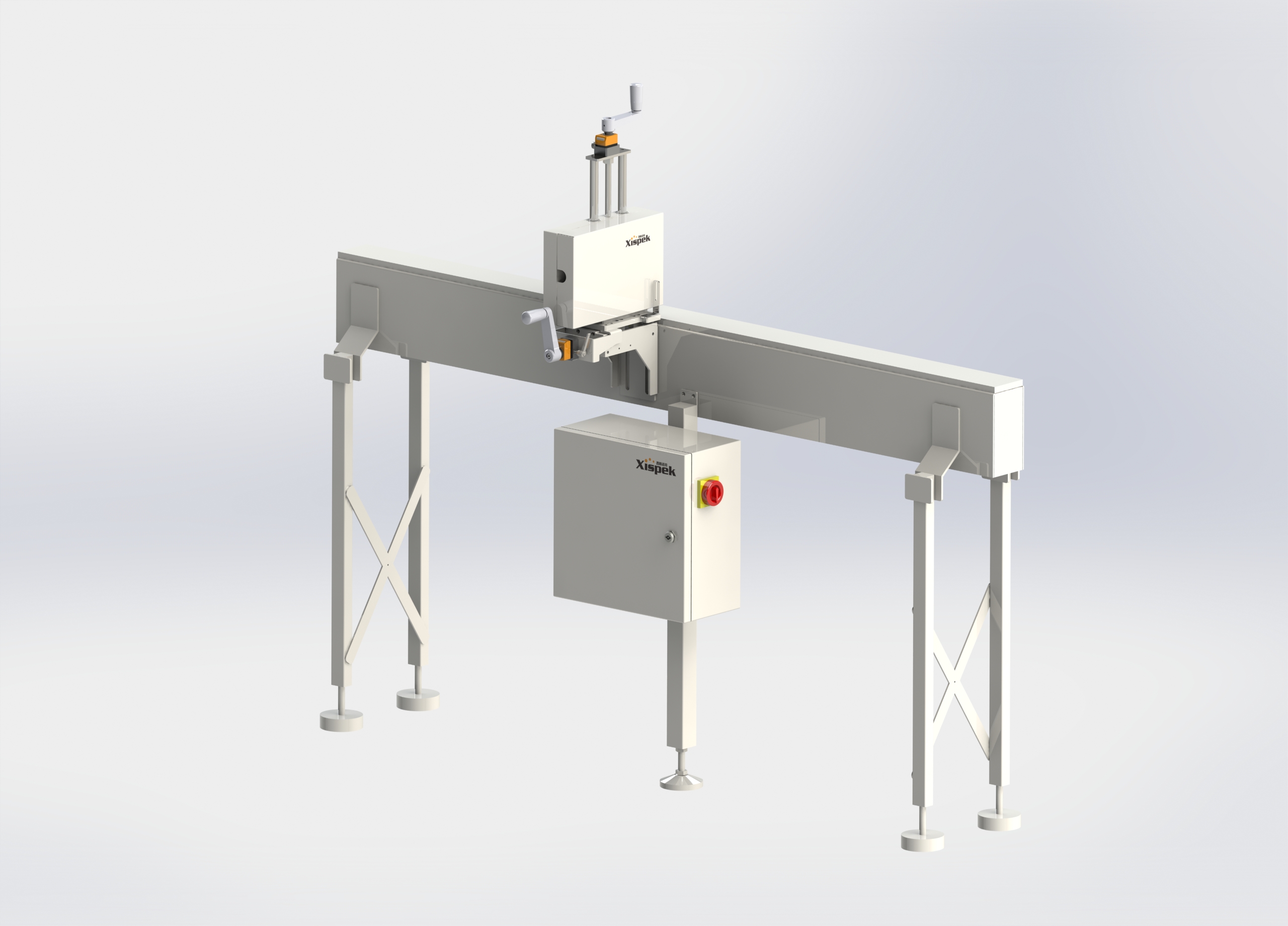

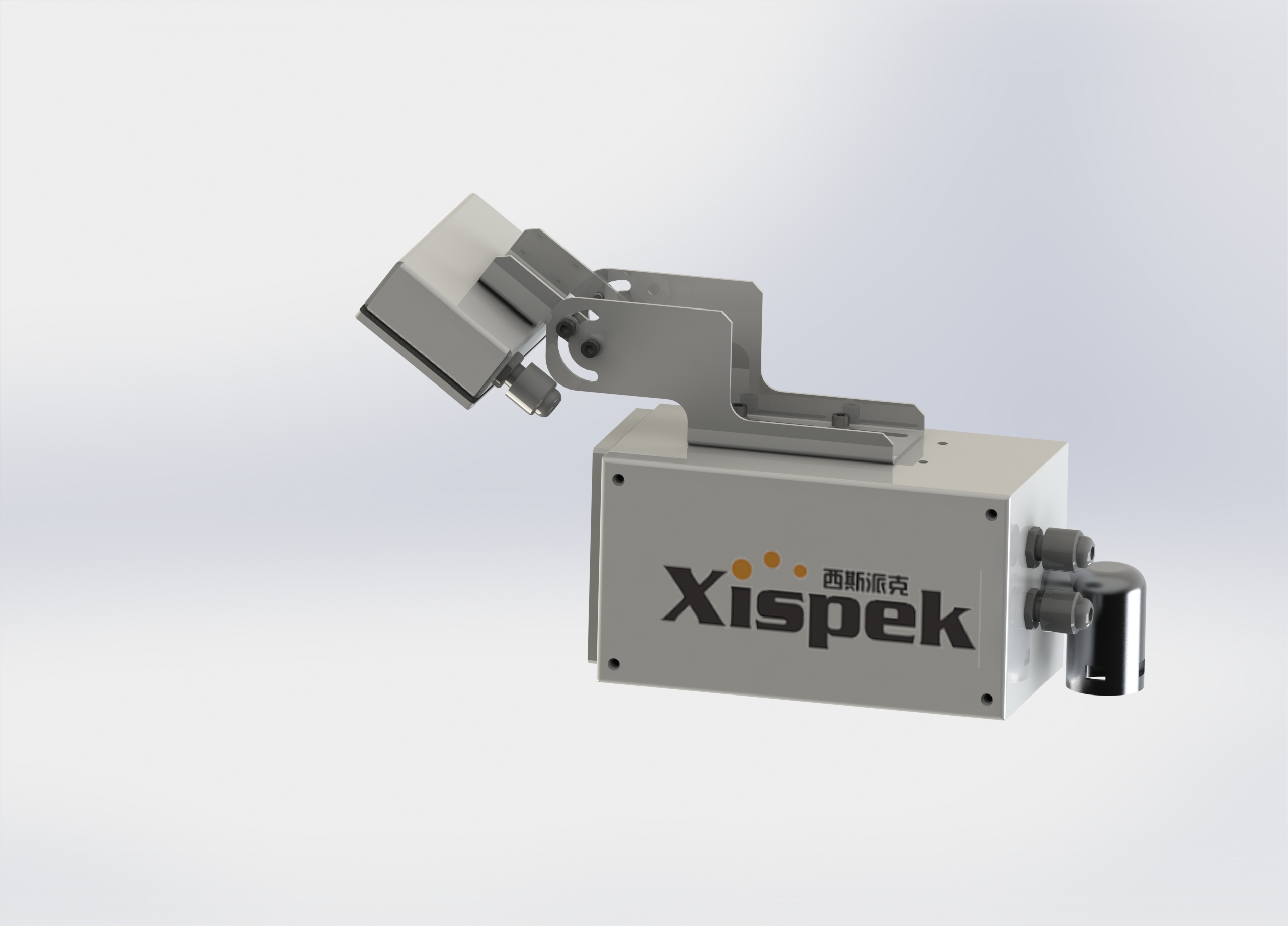

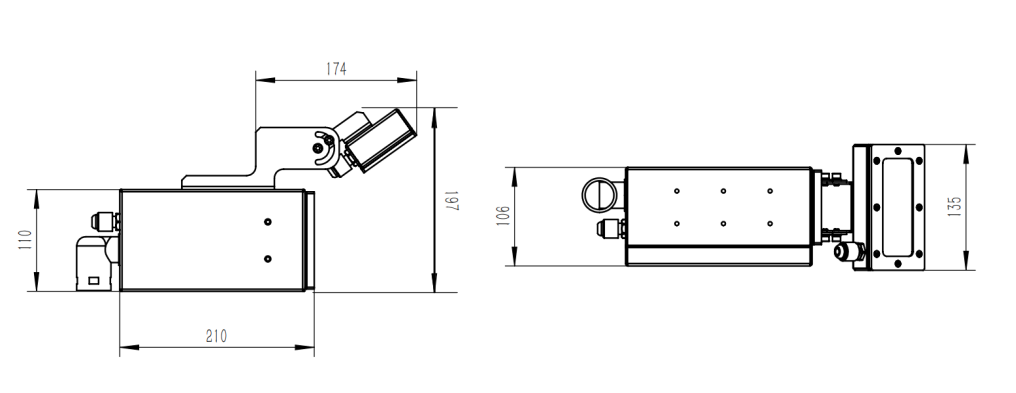

Label Inspection (LBI-G1) is a single inspection module installed after the labeling machine for label inspection, which can detect all kinds of defects on the front label. The module adopts a high-speed industrial camera and the independent XispVision® universal inspection software platform to accurately and efficiently identify the code and reject the defective products. The overall design is compact and flexible, and the angle of the light source can be adjusted to have a high degree of adaptability to the inspection of various codes.

|

Scope of Application:

|

Installation position:

|

Label presence or absence

Label presence or absence

Label misplaced

Label misplaced

Label position misalignment

Label position misalignment

Joint label (inside labeling machine)

Joint label (inside labeling machine)

|

|

|

| No label | Slant label | Not centered |

|

|

|

| High labelL | Low label |

Joint label |

Label inspection system is mainly used in the production line to inspect the labels after labeling and reject the unqualified products to prevent the defective products from flowing into the market. The inspection module can be installed inside the labeling machine, or outside the labeling machine on the conveyor . It can accurately and efficiently identify the slant labels, joint labels, and the presence or absence of labels.

The label inspection system adopts a modular structure, which can be matched with different control centers and other functional modules according to the speed of the production line.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Modular design is suitable for a variety of labeling machines

Modular design is suitable for a variety of labeling machines