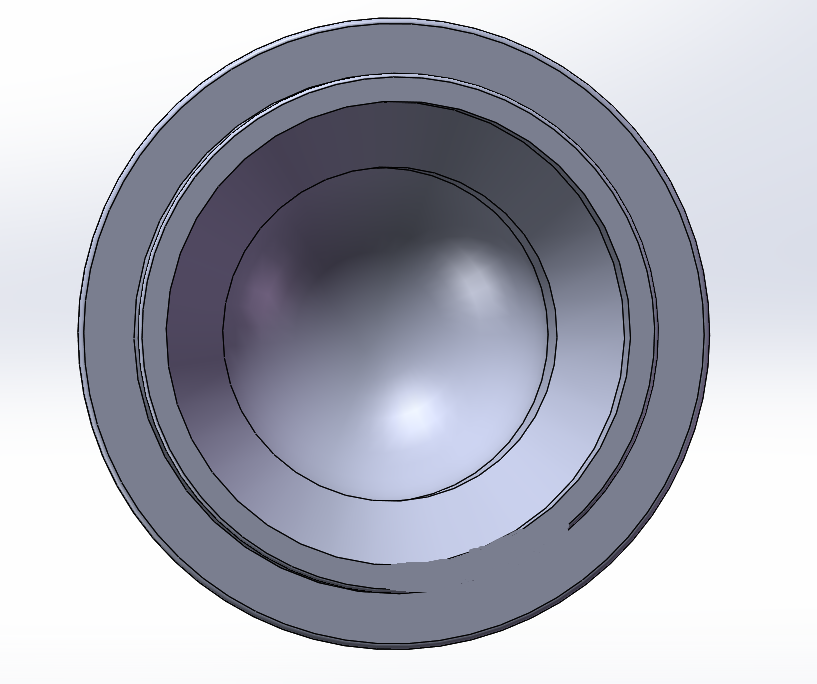

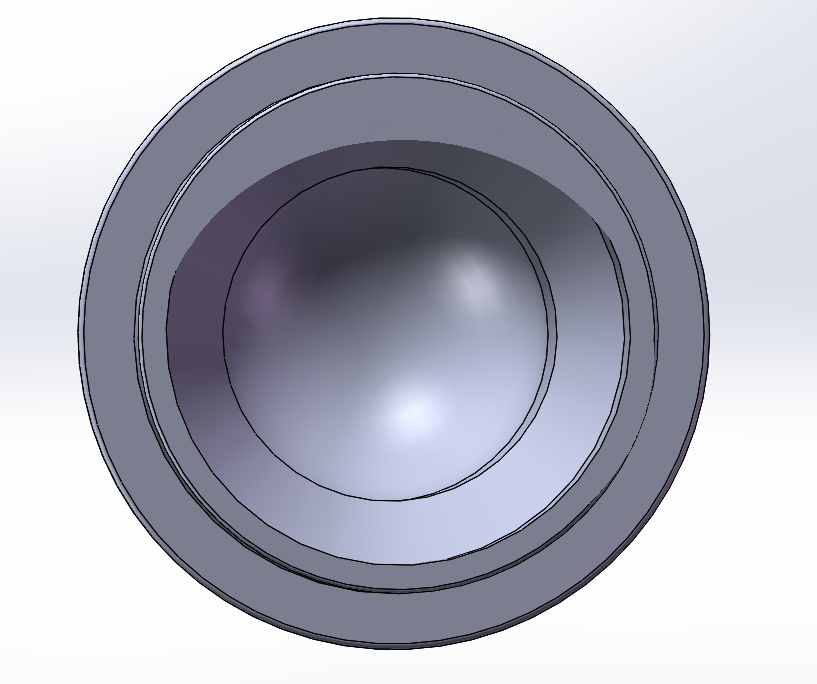

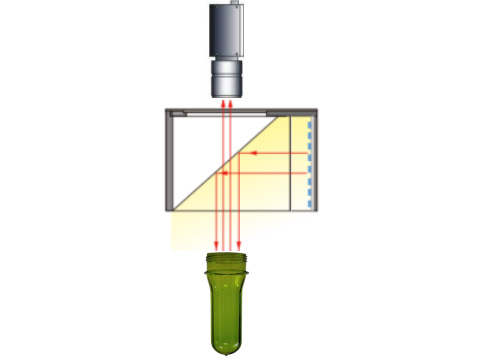

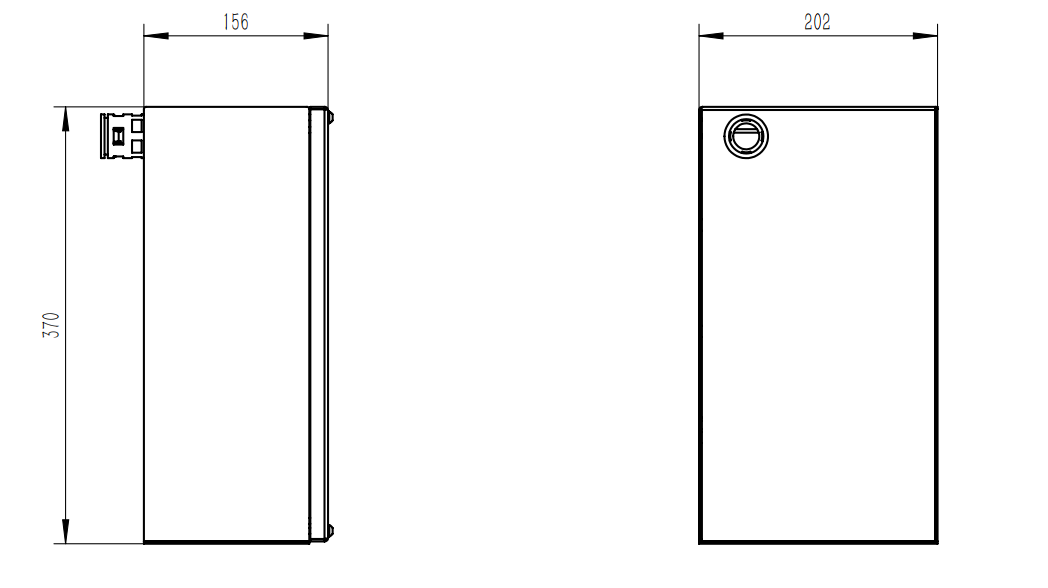

Preform Finish Inspection is a module installed in the blowing machine for inspection of preforms before blowing, mainly for inspection of preform size, gap, scratches and other defects, the highest speed up to 72,000 bottles/hour, using high-quality industrial cameras and maintenance-free LED light source, the overall design is compact and flexible, easy to install.

|

Scope of application:

|

Installation position:

|

Gap

Gap Size

Size Roundness

Roundness

Scratch

Scratch

|

|

|

|

Gap |

Scratch |

Notch Size |

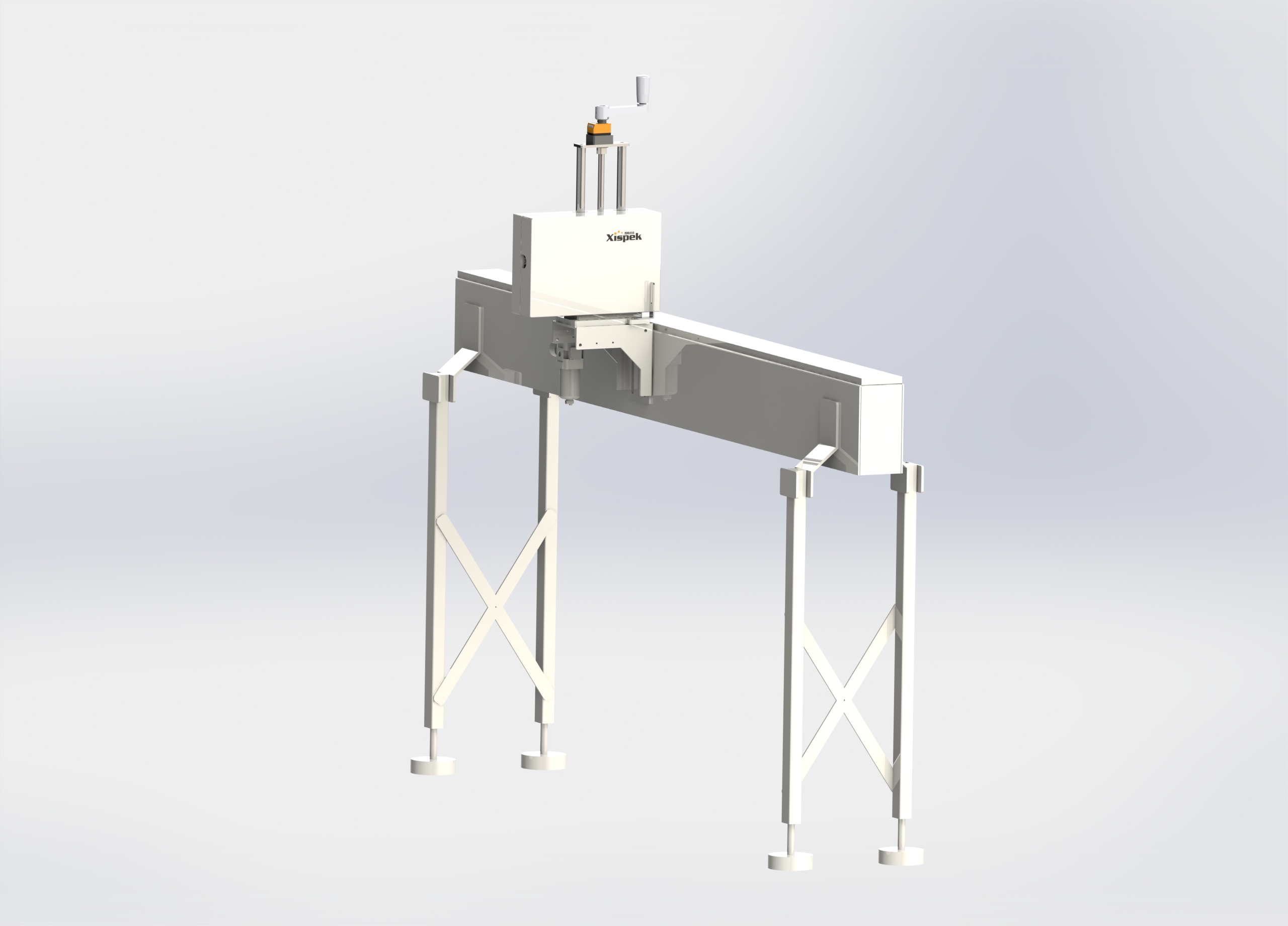

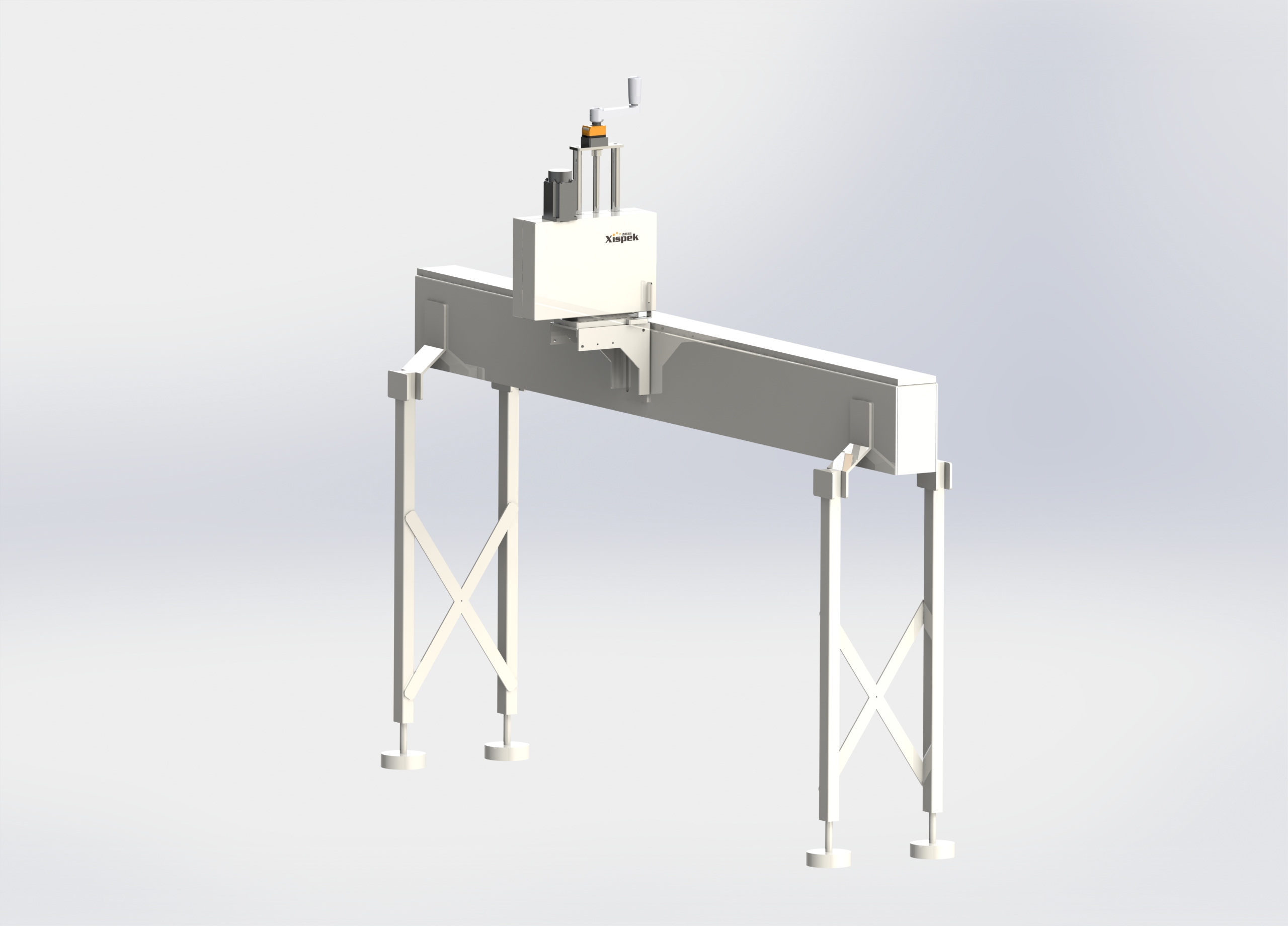

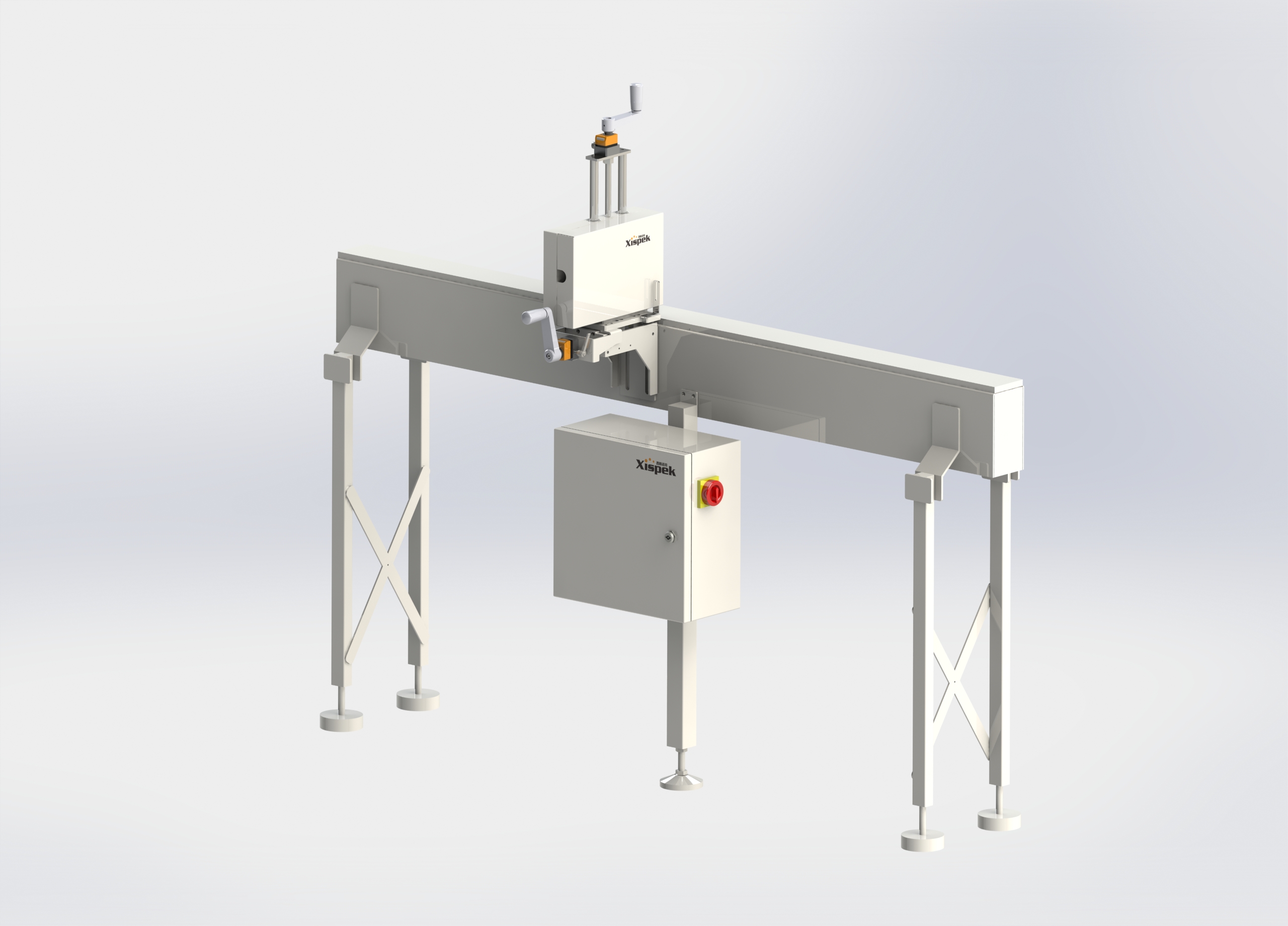

In the PET production line of the blowing machine, the inspection module is installed in the position after the preforms are arranged and before the blowing of the bottles to inspect the preforms one by one, the compact modular design enables the preform inspection to be installed in different sizes of the blowing machine, and the installation position of the inspection module is very flexible. Different control centers can be selected according to different production line speeds. Meanwhile, if the space inside the blowing machine allows, the inspection module of embryo body and embryo bottom can be installed to carry out all-around inspection on the embryo to ensure that every preform that enters into the blowing machine is qualified, which effectively improves the finished product rate of the blowing machine.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

Precise rejection with controlled intensity

Precise rejection with controlled intensity

Compact design for easy integration

Compact design for easy integration

IP65 protection level for various environment

IP65 protection level for various environment